A Buyer’s Guide to Used Excavator Parts

George Yang | Founder at EPO

Hi, I'm George Yang, here to share my expertise in excavator parts with you.

Table of Contents

Struggling to find a dependable source for used excavator parts? Securing quality components is crucial for maintaining the efficiency and longevity of your machinery.

As an industry specialist with extensive experience in aftermarket excavator parts, I understand how the right suppliers can significantly impact operational success.

When it comes to purchasing used excavator parts, the choices range from established authorized dealers to local repair shops. Each option offers its own advantages and challenges, making it essential to understand which source best fits your needs.

In this guide, you’ll learn about the most reliable sources for used excavator parts. You’ll also discover the benefits and drawbacks of each to help you make an informed decision.

So, let’s get started!

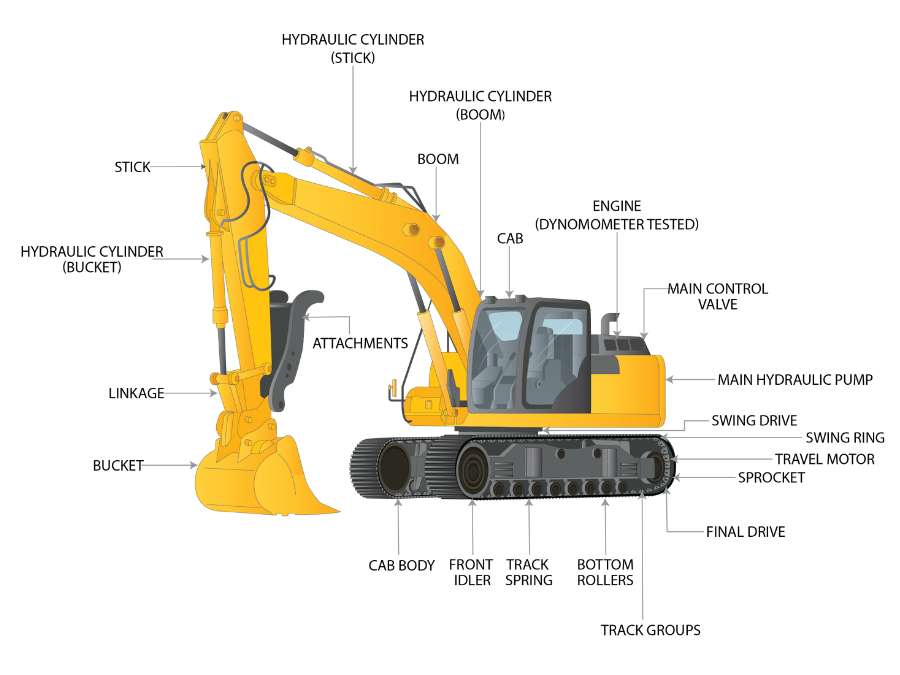

1. Overview of Excavator Brands and Parts

Excavators are essential machines for various industries, from construction to mining, and the demand for reliable parts to maintain them is always high. Let’s explore everything from the brands to the parts you may need, helping you make informed decisions for your equipment:

Excavator Brands:

- Caterpillar (CAT)

- Komatsu (PC)

- Volvo (EC)

- Hitachi (EX, ZAXIS)

- Sumitomo (SH, LS)

- Kato (HD)

- Kobelco (SK)

- Doosan (DH)

- Develon (DX)

- Hyundai (R)

- Sany (SY)

- XCMG

- LIUGONG

- Lovol

- SHANTUI

Hydraulic Parts:

- Hydraulic Pump

- Final Drives

- Auger Attachment

- Relief Valve (Main, Pressure, Swing Motor)

- Signal Gate Valve

- Unloading Valve

- Control Valve

- Joystick Assembly

- Walking Foot Valve Assembly

- Hydraulic Pump Assy

- Gearbox

- Motor

- Distribution Valve Assy

- Travel Motor Assy

- Swing Motor Assy

- Oil Separator Assembly

- Hydraulic Pump Parts:

- Cylinder Block

- Valve Plate

- Swashplate

- Servo Piston

- Hydraulic Pump Plunger Spring

- Hydraulic Pump Shaft

- Retainer Plate

- Copper Head

- Press Pin

- Hydraulic Pump Regulator

Electrical Parts:

- Sensors (Water Temp., Oil Pressure, etc.)

- Solenoid Valve (and variants)

- Alternator

- Motor Assy

- Starter Motor Assy

- Switches (Main Power Switch, Ignition Switch, etc.)

- Electric Fuel Pump

- Fuel Pump

- Controller

- Monitor

- AC Controller

- Wiper Motor Assy

- Wiring Harness (Hydraulic Wiring Harness, Monitor Wiring Harness, etc.)

- Lamp (Work Light, Turn Signal Lamp, etc.)

- Air Conditioning Accessories (Compressor, Blower, etc.)

- Small Electric Parts (Horn, Timer, Fuse Box, etc.)

- Battery

Other Components:

- Buckets

- Rubber Tracks

- Engines

- Cabs

- Doors

- Mulcher

- Tracks

- Undercarriage Parts

- Skid Steer Door

- Sheet Metal

- Engine Rear Cover

- Copper Head Gasket

While second-hand excavator parts might seem like a budget-friendly solution, EPO offers a more compelling option. With us, you can get brand new parts at the same or even lower price than used parts, all while enjoying the same quality as the leading brands. We maintain stocks for all excavator brands and offer a full range of parts, ensuring that whatever your equipment needs.

2. Benefits of Buying Used Excavator Parts

Choosing used excavator parts offers a practical solution for businesses looking to maintain efficiency while managing costs. This option provides several advantages that appeal to a range of operators, from small repair shops to large construction companies. Here are some benefits:

Cost-Effective Alternative

One of the main reasons to purchase used excavator parts is the significant cost savings. These components are typically priced much lower than new ones, allowing businesses to manage expenses without compromising on functionality. This can be especially beneficial for companies with tight budgets or those managing multiple pieces of equipment.

Accessibility of Parts

Used excavator parts are often more readily available, especially for older models that may no longer have new components in production. This makes it easier for businesses to find what they need quickly, reducing delays in repair processes. Such availability helps keep machinery operational, minimizing the impact on project timelines.

Supporting Sustainability

Opting for used parts also contributes to environmental sustainability by giving components a second life. This reduces waste and conserves resources, aligning with eco-friendly business practices. Many companies value this sustainable approach, which can also enhance their reputation among environmentally conscious clients.

Reliable Performance for Less

Reputable suppliers often refurbish and test used parts to confirm that they meet performance standards, providing a quality product at a lower price point. Many used components come from well-maintained machines, offering reliable functionality that businesses can trust. This balance of cost and reliability makes used parts a practical choice for many operators.

3. How to Inspect and Evaluate Used Excavator Parts

Proper inspection and evaluation are crucial when purchasing used excavator parts. These steps help determine the quality and suitability of the parts, preventing future operational issues and minimizing downtime. Here are six key points to guide you through the process:

- Visual Inspection for Damage: Start with a thorough visual check for cracks, rust, or signs of wear, as these can indicate potential issues. Parts that appear damaged or heavily corroded may not provide reliable performance.

- Verify Compatibility with Equipment Models: Confirm that the part matches the exact model and specifications required for the machinery. This step helps prevent mismatches that could result in equipment malfunctions or further damage to other components.

- Test Functionality Using Diagnostic Tools: For critical parts such as hydraulic systems or sensors, diagnostic tools should be used to evaluate their performance. These tests can reveal underlying issues that may not be visible during a simple inspection.

- Request Service and Maintenance Records: Obtaining maintenance history or service records related to the part provides valuable insights into its usage and condition. Such information helps determine whether the part has been properly maintained and its potential remaining lifespan.

- Examine Fit and Connections: Inspect all fittings, seals, and connectors to confirm they are intact and undamaged. Worn or loose connectors could lead to leaks or failures when the part is put into operation.

- Seek Expert Advice: Consulting with an experienced mechanic or industry expert can offer additional insights about the part’s condition and compatibility. Professional assessment aids in making informed decisions during the purchasing process.

4. Where to Buy Reliable Used Excavator Parts

Finding reliable sources for used excavator parts is crucial to avoid quality issues and operational delays. Various options exist in the aftermarket for obtaining high-quality components that fit specific machinery needs. Here are 4 common and dependable sources for purchasing used excavator parts:

Authorized Dealers and Distributors

Authorized dealers and distributors are often the most dependable sources for used excavator parts, particularly for well-known brands. These suppliers typically offer inspected and tested parts, reducing the risk of purchasing components that may fail prematurely. Although the prices might be higher than other sources, the added quality assurance and access to genuine parts make them a trusted option.

Specialized Aftermarket Suppliers

Specialized aftermarket suppliers, like EPO, provide a wide range of used parts that cater to various brands and models. These suppliers often refurbish parts and offer products at competitive prices, making them an attractive option for businesses seeking affordability without compromising on quality. Additionally, aftermarket suppliers usually have access to a broader inventory, especially for older or less common models.

Online Marketplaces and Industry-Specific Platforms

Online marketplaces and industry-specific platforms are convenient avenues for finding used excavator parts. For instance, platforms like Alibaba and other equipment-focused sites allow for quick searches and access to a global network of suppliers. However, when using these platforms, it is important to research the seller’s reputation and check for customer reviews to reduce the risk of obtaining unreliable parts.

Local Repair Shops and Salvage Yards

Local repair shops and salvage yards can be a practical choice for sourcing used parts, especially for older equipment. These establishments often have parts salvaged from decommissioned machines, offering them at reasonable prices. Working with local shops also provides an opportunity to physically inspect the parts before purchase, adding an extra layer of confidence in the quality of the components being acquired.

To better understand the benefits and considerations of each option, the following chart compares the different sources for buying used excavator parts. This overview covers aspects like price, availability, quality assurance, and convenience to help buyers make informed decisions.

| Source | Price Range | Availability | Quality Assurance | Convenience |

| Authorized Dealers and Distributors | High | High for newer models, moderate for older models | High (often genuine and tested) | Moderate; in-person visits may be required |

| Specialized Aftermarket Suppliers | Moderate | Broad range, including older models | Moderate to High (refurbished parts) | High; online and direct purchase options available |

| Online Marketplaces and Industry Platforms | Low to Moderate | Very High; global access | Varies (requires checking seller reputation) | Very High; convenient online browsing and purchasing |

| Local Repair Shops and Salvage Yards | Low to Moderate | Limited; focused on older, decommissioned parts | Low to Moderate (inspection may be needed) | Moderate; may require in-person visits for inspection |

This chart highlights that each source offers distinct advantages and potential drawbacks. Selecting the right option depends on factors like budget, availability of the part needed, and preference for quality assurance methods.

5. 3 Factors to Consider When Buying Used Excavator Parts

Buying used excavator parts requires careful consideration to avoid operational issues and maximize the value of the purchase. Here are 3 important factors to keep in mind:

#1 3,000-5,000 PSI Ratings

Compatibility is vital, particularly for hydraulic components that operate within a pressure range of 3,000-5,000 PSI (pounds per square inch) based on the excavator model. Always confirm that the part number matches the machine’s serial number and technical specifications to avoid performance issues. Cross-referencing these details with the equipment manual helps confirm that the part is suitable for installation.

#2 ±0.5% Accuracy and Correct Weight

Assessing the part’s condition involves inspecting its weight and testing for precision. For example, a track roller for a 20-ton excavator should weigh around 34 kg, while sensors should maintain an accuracy level within ±0.5% of their original specifications. Parts with significant deviations in these parameters may indicate wear or reduced functionality, leading to decreased performance.

#3 <2.5% Defect Rates

Evaluating suppliers based on defect rates and warranty terms is essential for securing dependable parts. According to Investopedia, the acceptable quality limit (AQL) for major defects, which are likely to cause failure, is typically set at 2.5%. Leading suppliers in the excavator parts industry strive to keep their defect rates well below this threshold, indicating strong quality control practices.

6. 5 Best Practices When Purchasing Used Excavator Parts

Following best practices when purchasing used excavator parts can help avoid issues and improve overall equipment reliability. Here are 5 key practices to keep in mind:

- Research Supplier Reputation: Investigate the background and reviews of suppliers before making a purchase. Reliable suppliers with positive feedback are more likely to offer quality parts and professional service, reducing the risk of receiving substandard components.

- Request Detailed Part Information: Always ask for detailed information about the part, such as its service history, compatibility, and any previous repairs. Having this information provides insights into the part’s condition and helps confirm if it meets specific machinery requirements.

- Inspect the Part Before Purchase: Whenever possible, conduct a physical inspection of the part to look for signs of wear, damage, or corrosion. This step allows for a better evaluation of whether the part will perform effectively once installed.

- Look for Warranty or Return Options: Choose suppliers who offer warranties or return policies on their used parts, as this provides some protection against defective items. A warranty demonstrates that the supplier has confidence in the quality of their products and offers recourse if issues arise after installation.

- Compare Prices Across Multiple Sources: To find the best deal, compare prices from different suppliers while taking quality into account. Price variations can often indicate differences in part quality or service, so balancing affordability with reliability is crucial for a worthwhile purchase.

Conclusion

Finding the right source for used excavator parts is crucial to maintaining the performance and efficiency of your equipment. Understanding the different options available, from authorized dealers to local repair shops, can help you make the best choice for your operational needs.

This guide has outlined key sources, highlighting their benefits and potential challenges, to assist you in making an informed decision. If you’re worried about unreliable suppliers, EPO has over 25 years of experience and a trusted presence in 80+ countries, partnering with top excavator brands. Contact us today to discover how we can provide high-quality, cost-effective solutions for your excavator parts needs.

Table of Contents

Recent Posts

Quick Quote

Fill out the form, get the quote in hours!

Recent Blogs

Sorry, we couldn't find any posts. Please try a different search.