Digger vs Excavator vs Backhoe: What’s the Difference?

George Yang | Founder at EPO

Hi, I'm George Yang, here to share my expertise in excavator parts with you.

Table of Contents

Ever wondered which machine is better for digging—a digger, an excavator, or a backhoe? Choosing the right one can save you time and money. Let’s break it down simply.

As a Mechanical Engineer with years of experience, I know how important it is to choose the right machine for the job. I’ll explain the differences so you can make better decisions.

A digger is a general term for any machine that digs. An excavator is a specific type of digger, strong and great for big jobs with its hydraulic arm. A backhoe is like a two-in-one machine that can dig on one side and load on the other.

In this guide, we’ll explore each machine’s job, what makes them different, and when to use them. Whether you work with machinery parts or do repairs, this will help clear things up.

Let’s get started!

1. What is a Digger?

A digger is a heavy machine used to dig, move soil, and handle large materials. It’s a general term that includes machines like excavators, backhoes, and trenchers. Each type of digger is built for specific tasks, but all help with heavy lifting and digging on construction sites and similar projects.

How Diggers Work

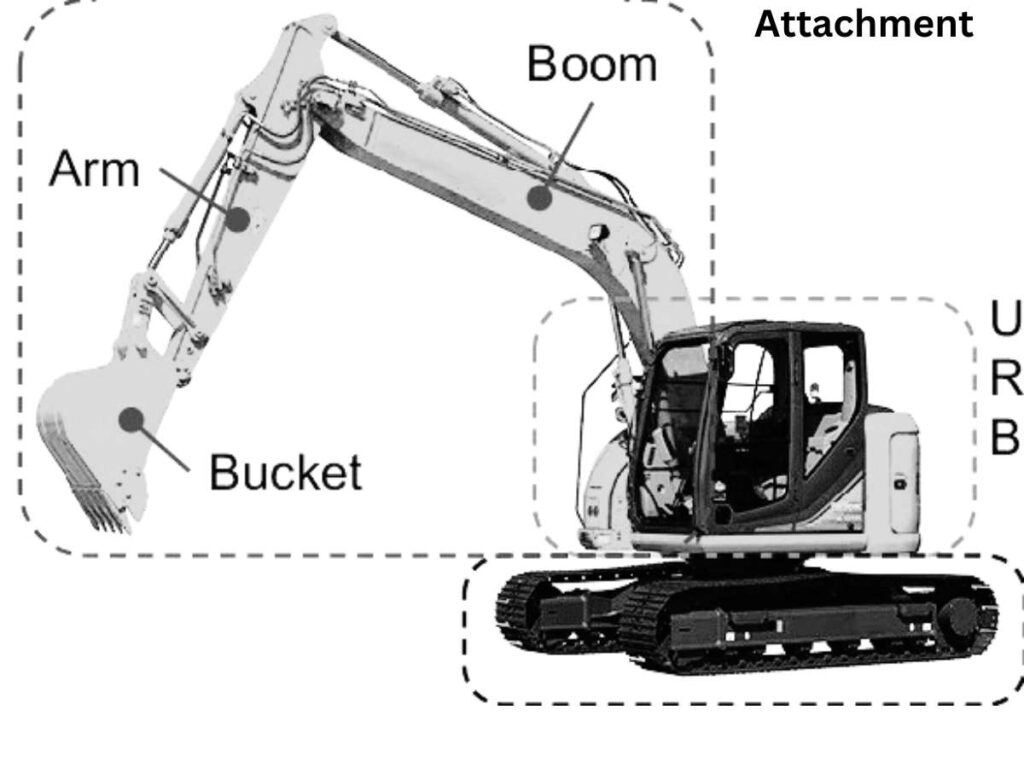

Diggers use powerful hydraulic systems to move their arms (booms) and buckets. These systems give them the force needed to dig deep into hard ground, lift heavy loads, and move materials. The operator sits inside a cab, controlling both the arm and the movement of the machine, which can be on tracks or wheels, depending on the model.

Key Features and Benefits of Diggers

Diggers come with important features that make them valuable on job sites. The table below shows how these features lead to practical benefits that boost productivity and efficiency:

| Feature | Benefit |

| Hydraulic Power | Provides strong lifting and digging force, speeding up heavy tasks like foundation digging and material handling. |

| Versatility with Attachments | Allows one machine to perform multiple tasks, reducing the need for additional equipment. |

| Mobility (Tracks or Wheels) | Enables the machine to move easily on rough or uneven terrain, making it suitable for different work environments. |

| Operator Comfort | Climate-controlled cabs and easy controls reduce operator fatigue, allowing for longer, more productive work hours. |

When to Use a Digger

Diggers are essential for a variety of tasks that involve moving earth or materials. Here are some common situations where using a digger makes the job easier:

- Excavating Foundations: Large diggers like excavators are perfect for digging the foundations of buildings or roads.

- Trenching for Utilities: Trenchers are the go-to machines for creating precise, narrow trenches for pipes or cables.

- Material Handling: Whether it’s loading dirt into trucks or moving rocks and debris, diggers with the right attachments can handle these tasks with ease.

- Clearing Land: Diggers can remove trees, rocks, and debris to prepare land for construction or landscaping.

2. What is an Excavator?

An Excavator is a type of heavy machine that’s mainly used for digging and moving large amounts of earth. It’s one of the most common machines on construction sites, known for its powerful hydraulic arm and ability to handle tough digging tasks with ease. As explained in industry research, excavators are among the most widely used equipment for earthmoving on job sites due to their efficiency and versatility.

How Excavators Work

Excavators use hydraulics to control a large arm with a bucket at the end for digging and lifting. They run on tracks, making them great for moving over rough ground. If you’re looking for reliable parts to maintain or repair your excavators, EPO offers 320,000 SKUs in electrical and hydraulic parts, providing everything you need to keep your machines working efficiently.

Key Features and Benefits of Excavators

Excavators are designed with features that make them powerful and versatile for a variety of tasks. Here’s a quick look at the key features and how they benefit your work:

| Feature | Benefit |

| 360-Degree Rotation | Lets the excavator rotate fully, making it easier to work in tight or hard-to-reach areas without moving the machine. |

| Precision Control | Offers accurate handling, which is great for tasks like trenching or grading, helping reduce mistakes. |

| Deep Digging Capability | Can dig much deeper than other machines, making it ideal for deep foundations or underground work. |

| Quick Attachment Change | Easily switch between tools like buckets, hammers, or augers, saving time and boosting efficiency on the job. |

When to Use an Excavator

Excavators are built for handling big, tough jobs. Here are some of the most common tasks where an excavator works best:

- Digging Foundations: Perfect for creating deep foundations for buildings or roads.

- Heavy Lifting: Great for moving large rocks, soil, or debris around a site.

- Demolition: With special attachments, they can tear down structures efficiently.

- Landscaping: Excavators can help shape the land, dig ponds, or create slopes and berms.

- Material Loading: Often used to load trucks with dirt, gravel, or other materials, speeding up construction processes.

3. What is a Backhoe?

A backhoe is a versatile machine with two main tools: a digging bucket at the rear (the “backhoe”) and a loading bucket at the front. This dual-function design makes it useful for both digging and moving materials, making it popular on construction sites for medium-sized jobs.

How a Backhoe Works

A backhoe has a hydraulic arm at the back with a bucket used for digging, and a larger bucket at the front for loading materials. The operator can rotate the seat to face either side, depending on which tool is needed. The machine usually runs on wheels, allowing it to move easily between tasks on the job site.

Key Features and Benefits of a Backhoe

Backhoes are designed to be flexible machines, combining digging and loading capabilities in one. Here’s a breakdown of their key features and the benefits they bring:

| Feature | Benefit |

| Dual-Purpose Design | Combines a digging bucket and a loading bucket, so one machine can handle both tasks. |

| Compact Size | Smaller than an excavator, making it easier to navigate tight spaces or small job sites. |

| Wheeled Mobility | Moves quickly on roads or around the site without damaging the ground, unlike tracked machines. |

| Quick Tool Switching | Allows the operator to easily switch between digging and loading, increasing job site efficiency. |

When to Use a Backhoe

Backhoes are perfect for jobs that require both digging and loading in one machine. Here are a few common uses:

- Small to Medium Excavation: Great for digging trenches, holes, or foundations on smaller projects.

- Material Transport: The front bucket makes it easy to move dirt, gravel, or other materials around the site.

- Utility Work: Ideal for digging up old pipes or laying new ones in tight spaces.

- Road Maintenance: Backhoes are used for filling potholes or clearing snow and debris from roads.

- Light Demolition: Equipped with a breaker attachment, backhoes can handle small demolition jobs, like breaking concrete or asphalt.

4. Key Differences Between Diggers, Excavators, and Backhoes

While diggers, excavators, and backhoes are all used for moving earth, they each serve different purposes and have unique features. Here’s a simple breakdown of their main differences:

| Machine | Purpose | Size | Main Features | Best For |

| Digger | General term for earth-moving machines | Varies widely, depending on the machine (small to large) | Covers multiple machines like excavators, backhoes, and trenchers | Broad range of digging and material handling tasks |

| Excavator | Heavy-duty digging and lifting | Typically large, built for heavy-duty tasks | Hydraulic arm, 360-degree rotation, runs on tracks | Large-scale digging, demolition, deep foundations |

| Backhoe | Dual-function digging and loading | Medium-sized, smaller than most excavators | Has a rear digging arm and front loading bucket, runs on wheels | Smaller jobs, utility work, material transport |

5. 4 Tips for Choosing the Right Equipment for Your Project

Selecting the right machinery for your project can save time and resources. Below are some key considerations to help you make the best choice for your specific needs:

#1 Type of Work

Identify the specific job you need the machine for. If you need deep digging for foundations, an excavator is a better fit. For smaller jobs that require both digging and loading, a backhoe offers more versatility. Choose based on the type of work—digging, loading, trenching, or demolition.

#2 Size and Power

Consider the machine’s size and power output relative to the job. Larger machines like excavators provide more power and reach, making them ideal for heavy-duty work, while smaller machines like backhoes can navigate tight spaces and handle lighter tasks. The right size helps you get the job done faster without using excessive power.

#3 Depth and Reach Requirements

Think about how deep you need to dig and how far you need to reach. Excavators have longer arms and greater digging depth, making them perfect for deep trenches or foundations. Backhoes, while versatile, have a more limited reach and are better suited for shallow digs and material handling. For example, a deep excavation for a commercial building foundation would be better suited for an excavator.

#4 Attachment Needs

Think about whether you’ll need specific attachments, such as hammers, augers, or grapples. Excavators often have a wider range of attachments available. For instance, if your project requires breaking concrete and digging, an excavator with a hydraulic hammer is a good choice. At EPO, we offer 1:1 product development with 99.99% accuracy, providing the exact excavator parts you need for your projects.

Conclusion

Digger, excavator, and backhoe may seem alike, but each serves a different purpose. Knowing their differences helps you pick the right machine for the job. Whether it’s digging or material handling, using the correct equipment boosts efficiency.

We hope this guide has helped you better understand which machine suits your project needs. Choosing the right supplier is just as important, and unreliable suppliers can cause costly delays. With 25 years in the business and trusted in over 80 countries, EPO partners with top excavator brands to provide dependable electrical and hydraulic parts. Contact us to keep your equipment running smoothly!

Table of Contents

Recent Posts

Quick Quote

Fill out the form, get the quote in hours!

Recent Blogs

Sorry, we couldn't find any posts. Please try a different search.